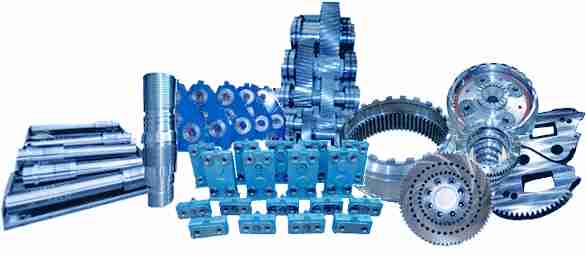

At Delta Dynamics we have decades of machining experience and we provide our clients with precisely designed power transmission solutions.

We like taking on unusual and challenging engineering requests.

We provide industrial gear box services, gear reducer failure, reducer rebuilds, and other machining services.

We always provide our design experience and offer suggestions.

Mining

Mining